By Bill Kreuser, PhD

Repeated applications of the same type of pest control product can increase the likelihood of pesticide resistance. Many of today’s pesticides are more elegant than products from several decades ago. Instead of targeting many aspects of a pest’s biochemistry or physiology, most newer products impact a very specific process that either kills or slows the growth of a pest. This generally increases the specificity of an active ingredient for the target pest and increases the safety for non-target organisms.

Pesticide resistance occurs when an individual pest organism develops a change or mutation that allows it to tolerate a pest control product. In most cases, resistance development is a continuum of tolerance where the more tolerant pest has an advantage over less tolerant pests. Through reproduction, resistance genes can spread to a pest’s offspring and a resistant population can develop. Sometimes pests can develop rapid or complete tolerance to an active ingredient. For example, the dollar spot pathogen can develop complete resistance to the active ingredient thiophanate-methyl with only one small genetic change. On the other hand, the dollar spot pathogen needs to develop several mutations to develop resistance to other fungicide chemistries like the demethylation inhibitors (DMIs), so resistance develops in a slow and gradual manner. Slow and gradual resistance development is often first seen as a reduced length of control, for instance a fungicide that used to give 21 days of control but now only gives 14 days.

There are international boards of expert scientists that group different insect, weed and disease control ingredients (insecticides, herbicides and fungicides) into different groups or classes (IRAC, HRAC, FRAC). Ingredients in these different classes have very similar modes or mechanism of action. This allows pests to develop resistance in similar ways. When applying pesticides, it’s important to know the resistance to products group/class to avoid applying the same type of control product repeatedly. Many pesticide manufactures are now putting these group/class numbers on the front of their product label (Fig 1).

One way to reduce the risk of resistance is to minimize the number of applications for a particular pest. The more times an ingredient from a particular resistance group/class is applied increases the risk of resistance development. Different pest models exist to help avoid unnecessary applications (i.e. Smith-Kerns dollar spot model, grassy weed emergence models, annual bluegrass weevil models).

Another way to minimize resistance development is to alternate or rotate resistance groups when making repeated applications for a pest. For example, a dollar spot control program might have ingredients from FRAC groups 3, 7 and 11. Mixing multiple ingredients from different groups during an application can also reduce the risk of resistance, as long as all the active ingredients in the mixture control the pest of concern. The pest would need to evolve two or more mechanisms of resistance at the same time to overcome that ingredient mixture.

There are some ingredients that work at multiple locations in a pest. These “multi-site” materials have a much lower risk of resistance. A well-known example is the fungicide chlorothalonil (FRAC Group M5). It has very low risk of resistance development but can also impact many other non-target organisms. There has also been increased regulatory pressure to restrict or remove some of these products from use in turfgrass systems. Turfgrass managers will need to rely on other chemistries to fill these gaps.

Resistance management for turfgrass pests is a real concern. Fewer and fewer new pest control products are coming to the turf industry, so it’s critical we manage the ones we currently have. There are strategies to minimize and slow this risk. It’s important to know a product’s active ingredients – and their resistance groups or classes –to stay ahead of this problem. Finally, there are tools out there that can help managers select appropriate products including the Turfgrass Weed Control for Professionals, Chemical Control of Turf Diseases, Tennessee’s Mobile Weed Manual and UW’s new Turf Pest Management Mobile app.

Application Advisor Guides Product Selection in GreenKeeper App

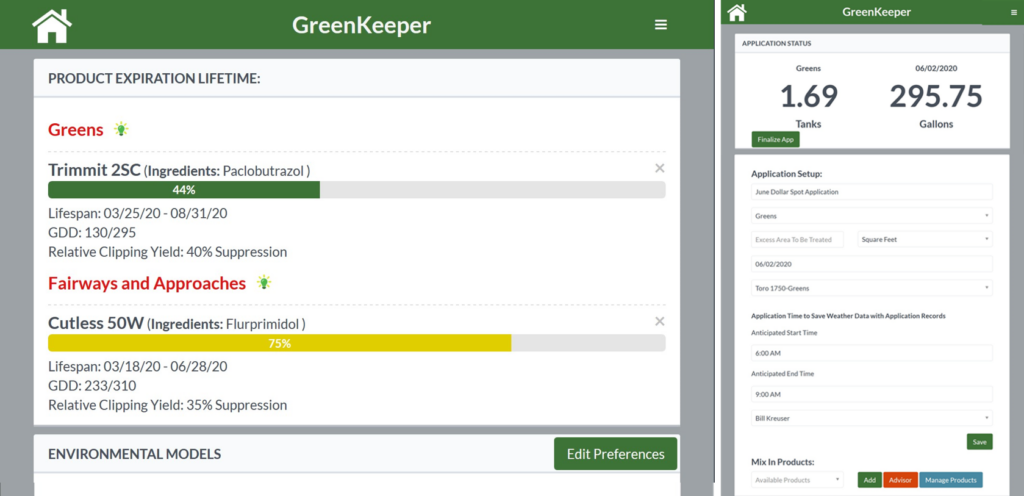

Application Advisor is a new 2020 GreenKeeper Premium improvement that helps analyze past applications to select the best control product for a particular pest. It provides users both product control (efficacy) guidance and rotation management support. We’ve partnered with top turfgrass pathologist, entomologist and weed scientists to code product efficacy data into GreenKeeper.Application Advisor can be found in two place. The first is the green light bulb symbol on the ‘Product Expiration Lifetime’ dash. It is also located on the ‘New Application’ page when products are being added to a mix (Fig. 2). Clicking the Application Advisor button will initiate Application Advisor for the selected area. For example, the button on across from the ‘Greens’ area in Fig. 2 would analyze past applications to only the Greens at a course.

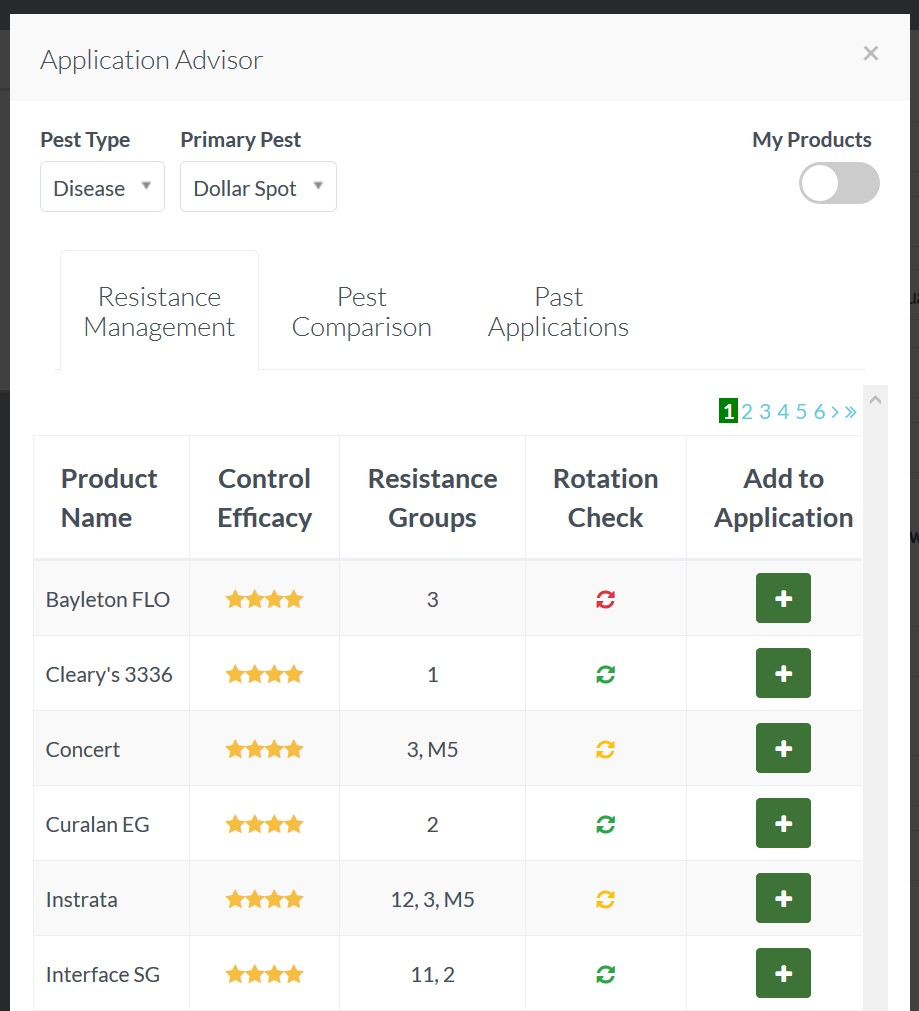

Next, users select the pest type, species, and PRE/Post (for weed and insect control) to engage Application Advisor’s analysis. The system will search backwards through all the past applications to identify recently applied products that control the pest of interest (Fig. 3). It will also populate and rank all of the products in your inventory that control that pest. Users can view all the products in the GreenKeeper database by de-selecting the ‘My Products’ toggle switch at the top of the page. Users can also compare pest control efficacy for other pests on the ‘Pest Comparison’ tab.

Figure 3. Application Advisor selection guidance based on product efficacy, product application history, and rotation management awareness.

The color of the rotation symbol help GreenKeeper users visualize how pesticide ingredient group/classes are being rotated (Fig. 4). Green means that product has a different resistance group/class than the ingredient from the past application. Red circles indicate the selected product is of the exact same group/class as the last application. It would be good practice to use a different product to minimize the risk of resistance development, if possible. Products with very low resistance risk, i.e. chlorothalonil, would always be green. Finally, yellow symbols indicate the selected product or products from the most recent application contain two or more ingredients from different resistance classes. By mixing ingredients, the risk of developing resistance is reduced.

With the right information and thoughtful product selection, you can minimize the risk of rapid pesticide resistance at your facility. Application Advisor uses the latest product efficacy and rotation management BMPs to help sustain product longevity. This saves you money and produces consistent pest control results.